Motorised headstock

Progress has entered also the bell sector, so linked to traditions, with the merit to keep the sound bells considering the decrease of the bell ringers.

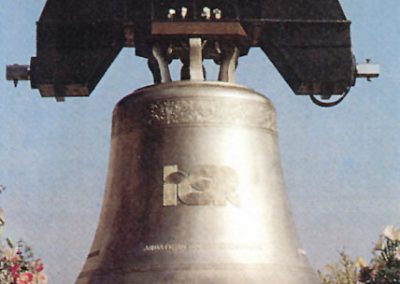

The rope was substituted by a chain activated through an electrical motor. Later, this solution has been definetely improved introducing the motorised headstock 81, a product conceived and realised by A.E.I. Di Perego. The motorised headstock 81 and the following versions, which have improved its performances and reduced the production costs, are the only real innovation in the bell automation plants field. Apart from the motorised headstock, all existing systems are adjustments of practical utility applied to the pre-existing manual systems which used rope running through wheels.

In this context, the motorised headstock has given birth to a new bells automation era.

The motorised one is a supporting headstock resembling the classic wooden one but made of steel. It also inlcudes the moving elements, getting rid of the outer wheel, chain and motor. It has the double function to support the bell and give the normal swinging movement to the “running”, “heaping” and “mouth up” sounds, in full compliance with the local costums.

The motorised headstock offers more advantages than the traditional one:

- NO OUTER WHEEL, CHAIN OR MOTOR IN VIEW and the bell beauty can be more appreciated, giving the designer the freedom to custom with limitless imagination and realising the bell tower (or the bell framework) with an air line adaptable to the church shapes.

- HIGHEST PROTECTION OF ALL EQUIPMENT kept in a watertight environment and getting evident duration advantages. Advantages even more important in polluted environments, very cold zones or in the ones subject to high corrosion like marine areas.

- REDUCED INSTALLATION COSTS since the motorised headstock bell is placed on the towerbell supports when already tested in the workshop – it is ready to be connected to the Sacristy control board through cable or radio.

- REDUCTION OF THE DYNAMIC STRESS compared to the traditional plant having separated wheel and motor.

- EXCLUSION OF VIBRATIONSthanks to the use of cushioning elements, calculated depending on the involved weights. This application is particularly important in case of restorations that underline structural cracks or deficiencies or in case of buldings made of reinforced concrete in which the bell transmits, through the structure, noises unbearable for believers and unsustainable for glass walls

- SMALLER FOOTPRINTS IN THE BELL CHAMBER: in fact the motorised headstock reduces the bell overall dimensions since the space required for the motor, the ropes and the wheels is not necessary.