Traditional headstocks

The bell headstock is a structure made of cast iron (or wood, or steel) and it functions as a support of the bell through the ironware duly bolted; between the headstock and the bell there is an isolator, generally made of wood, to damp the mechanical vibrations and the recoils, produced by the bell when moving.

The counterweights constitute the superior part of the ambrosiano headstock that, filled with iron plates, balance and slow the bell rotation down. The counterweights of the typical “ambrosiano” headstock (sometimes of other kinds of headstocks too) are knobs having at the bottom tie-rods that stop the plates inside the headstock. The feature that makes the traditional headstock, either “ambrosiano” or “running”, differently than the motorised one, is that the transmission mechanical devices (wheel and chain) are directly fixed to the headstock and are clearly visible.

Ambrosiano headstocks

They are heavy headstocks, that is they are very counterbalanced, and because of this fact the bells can do more or less slow swings, producing, therefore, a series of tolls spaced from each other. Being well balanced, they easily achieve the “mouth up” position, that is they easily do a 360° rotation after a few swings. In this kind of bells the clapper is hooked higher than the rotation pin height and therefore it always strikes the lower part of the the bronze bell. The clapper has an ideal weight, rapporting to the bronze bell, equal to 1,8% – 2%.

Details

When this headstock is used in the classical system “ambrosiano – lombardo” the clapper is hooked higher than the rotation pin, producing very slow swings and, therefore, tolls well spaced from each other. In the “ambrosiano – ligure and veronese” system, the headstock hook is close to the rotation pins height so it produses less slow swings and tolls less spaced from each other.

For the execution of the concerts it is necessary, first of all, to move the bells in vertical position with the mouth up and to stop them in this position.

Afterwards each bell is moved from the vertical position through a light pulling of the rope or through the releasing of the motor brake. In this way the bells let themselves fall and emit the sequence of notes desired.

In the pure “ambrosiano” system the tolls alternate remaining precisely separate from each other without overlapping. In the “bergamasca” variation, on the other hand, overlapping of two or more bells occurs in the bar, creating chords. The “ambrosiano” sound system is typical of Lombardia region but it has also spread in other areas of the north of Italy, particularly in Piemonte, Liguria and Verona area.

Running headstocks

They are light headstocks, that is they are poorly counterbalanced, and because of this fact the bells can do fast swings, producing, therefore, a series of tolls with little space from each other.

In this sound system the clapper is hooked under the rotation pins and therefore it always strikes the upper part of the bronze. The clapper, which is usually heavier than the other mounting systems, has a characterist elongated shape making rather heavy its lower part. Its weight is around 3% – 5% of the bell’s one.

Details

The bell, during the sound, reaches an arc of rotation between 90° and the 180°, and the clapper hits the upper part of the bell. Immediately after the blow, the clapper detaches from the bell not damping the harmonics and letting the bell’s vibrations free, unlike the counterbalanced “ambrosiano” system. For this reason “running” bells make sound vibrations much more lasting and pleasant. This system is very popular throughout Europe.

In Italy the “running” system is used in some northern regions, in particular Trentino, Alto Adige, nort-eastern Veneto, Friuli Venezia Giulia, Valle D’Aosta, in some Piemonte areas close to the French border and in some Lombardia areas like Valtellina. The “bolognese” system, widespread in Emilia Romagna, is a full rotation system being part of the “running” system.

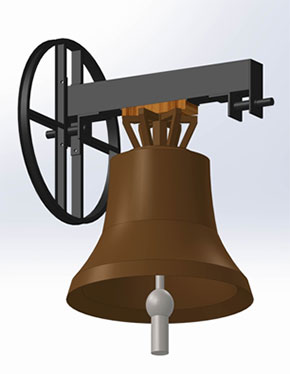

Motorised headstock vs. traditional headstock

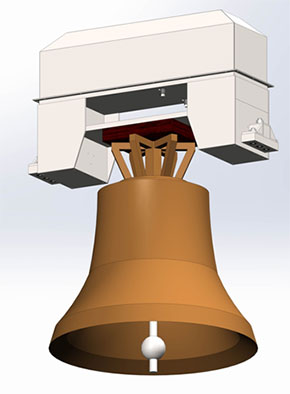

The motoriszed headstock is a product conceived and realised by A.E.I. Di Perego in 1981 with the first model 81. The following versions have improved its resistance and duration performances and have reduced production and maintenance costs.

The motorised headstock is a steel support similar to the wooden one. The motorised headstock includes the moving mechanics devices, making the outer wheel, chain and motor not necessary. It has the double function to support the bell and give the normal swinging movement; it can be used either in the “running” system or in the “ambrosiano” one, in full compliance with the local costums.

Details

The motorised headstock offers more advantages than the traditional one:

NO OUTER WHEEL, CHAIN OR MOTOR IN VIEW and the bell beauty can be more appreciated, giving the designer the freedom to custom with limitless imagination realising the bell tower (or the bell framework) with a more harmonious line than the church shapes.

HIGHEST PROTECTION OF ALL EQUIPMENT kept in a watertight environment and getting evident duration advantages. Such an advantage is even more important in polluted environments or in the ones subject to high corrosion like marine areas.

REDUCED INSTALLATION COSTS since the motorised headstock bell is placed on the towerbell supports when already tested in the workshop – it is ready to be connected to the Sacristy control board through cable or radio.

REDUCTION OF THE DYNAMIC STRESS AND VIBRATIONS compared to the traditional plant having separated wheel and motor. Result achieved thanks to the use of cushioning elements, calculated depending on the involved weights.

SMALLER FOOTPRINTS IN THE BELL CHAMBER: in fact the motorised headstock reduces the bell overall dimensions since the space required for the motor, the ropes and the wheels is not necessary.